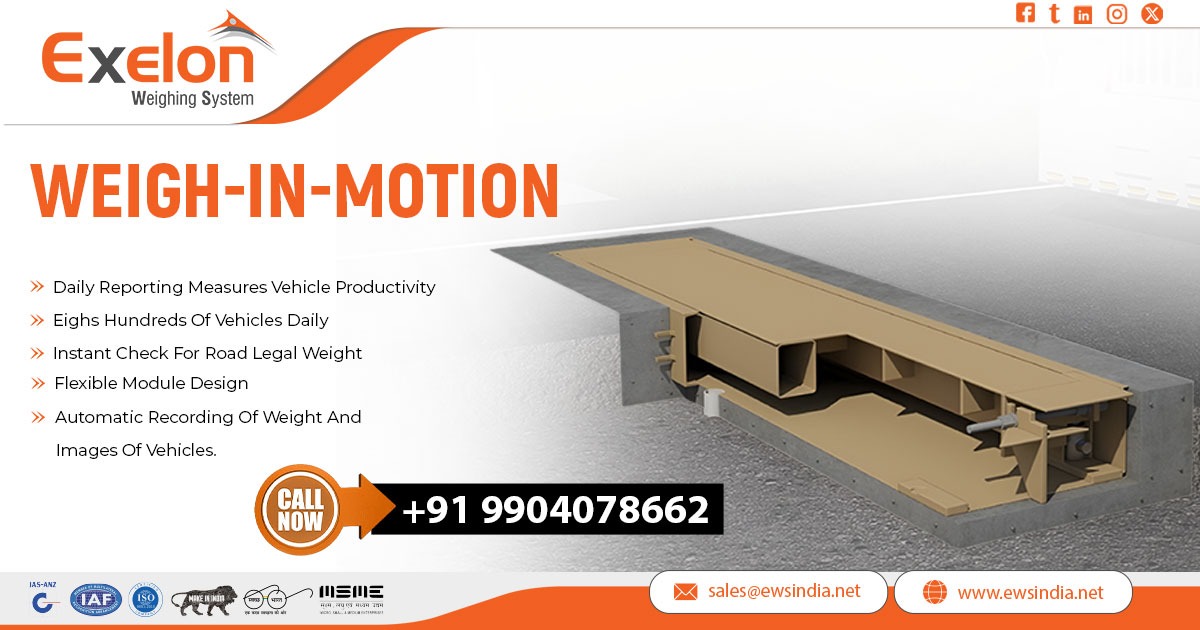

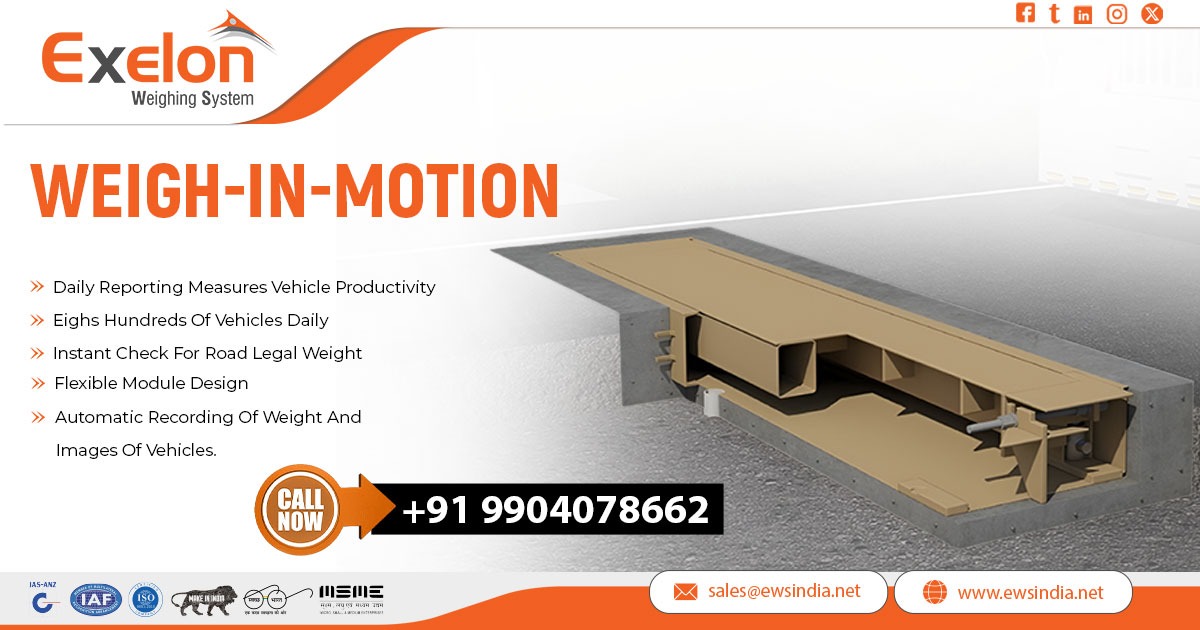

Exporter of Weigh in Motion in Cameroon

Exelon Weighing System is a leading Manufacturer, Supplier, and Exporter of Weigh in Motion in Cameroon. Our manufacturing plant is in Ahmedabad, Gujarat, India. A

Exelon Weighing System is a leading Manufacturer, Supplier, and Exporter of Weigh in Motion in Cameroon. Our manufacturing plant is in Ahmedabad, Gujarat, India. A

Exelon Weighing System is a leading Manufacturer, Supplier, and Exporter of Multi-Axle Weighbridge in Senegal. Our registered office and manufacturing unit are located in Ahmedabad,

Exelon Weighing System is a leading Manufacturer, Supplier, and Exporter of Single Axle Weighbridge in Ethiopia. Our registered office and manufacturing unit are located in

Exelon Weighing System is a leading Manufacturer, Supplier, and Exporter of Solar-powered Weighbridge in Ethiopia. Our registered office and manufacturing unit are located in Ahmedabad,

Exelon Weighing System is a leading Supplier, Manufacturer, and Exporter of Off-Road Weighbridge in Mozambique. Our registered office and manufacturing unit are located in Ahmedabad,

Exelon Weighing System is a leading Manufacturer, Supplier, and Exporter of On-Board Weighing in Gambia. Our registered office and manufacturing unit are located in Ahmedabad,

Exelon Weighing System is a reliable Manufacturer, Supplier, and Exporter of Weigh Pad in Mauritania. Our registered office and manufacturing unit are located in Ahmedabad,

Exelon Weighing System is a trusted Manufacturer, Supplier, and Exporter of Multiple Deck Weighbridge in Cameroon. Our registered office and manufacturing unit are in Ahmedabad,

Exelon Weighing System is a leading Manufacturer, Supplier, and Exporter of Unmanned Weighbridge in Mozambique. Our registered office and manufacturing unit are located in Ahmedabad,

Third Floor, 15-B, Gopikunj Society, Behind Pragati Nagar Garden, Ahmadabad – 380013 Gujarat, India

09904078662

09904078664

sales@ewsindia.net

Third Floor, 15-B, Gopikunj Society, Behind Pragati Nagar Garden, Ahmadabad – 380013 Gujarat, India

WhatsApp us